CNC Iintlobo zokuguqula intsimbi / i-aluminiyam eguquguqukayo yokudibanisa kwimoto

Ukudityaniswa kwemihlathi egobileyo

Udibaniso lwe-Curved Jaw lunokusetyenziswa kwizicelo ezininzi kwaye lusebenza njengenjongo yokudibanisa yonke into.Uyilo olusisiseko lwe-Curved Jaw luvumela umthamo we-torque ephezulu kwi-compact design.Izinyo eligobileyo linendawo enkulu yokunxibelelana enika amandla aphezulu e-torque, kwaye inciphisa uxinzelelo lomphetho.Iya kwamkela i-axial, i-radial kunye ne-angular shaft misalignments.

Ii-hubs ziveliswa kwizinto ezahlukeneyo ezibandakanya: i-aluminiyam, ingwevu, intsimbi, intsimbi, intsimbi ene-sintered, kunye nentsimbi engatyiwayo.Izinto zesigcawu ziyafumaneka kwiinketho ezahlukeneyo ze-durometer kwi-Urethane & Hytrel.Izigcawu ziyakwazi ukusebenza phantsi kweemeko zesiqhelo zomjikelo ukuya kwimijikelo enzima equka ukulayisha umothuko kwaye inokunciphisa ukungcangcazela okushukumayo kwisixokelelwano.

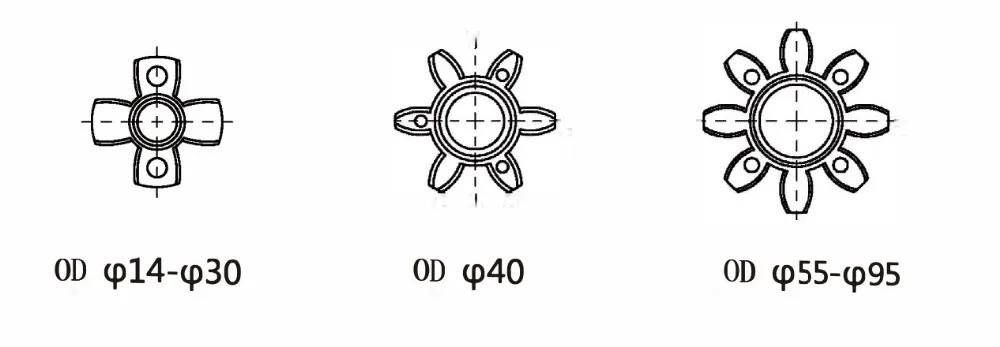

| Umzekelo | Ubungakanani bombhobho (mm) | Ikaliwe iTorque (Nm) | I-MaxTorque(Nm) | Isantya esiphezulu | Ububanzi bangaphandle (mm) | Ubude (mm) | Unyamezelo lweBore (mm) |

| I-HS -TCN-14C | 3~7 | 0.7 | 1.4 | 45000 | 14 | 22 | +0.6~0 |

| I-HS-TCN-20C-R | 4~11 | 1.8 | 3.6 | 31000 | 20 | 30 | +0.8~0 |

| I-HS-TCN-30C-R | 6-16 | 4 | 8 | 21000 | 30 | 35 | +1.0~0 |

| I-HS-TCN-40C-R | 8–28 | 4.9 | 9.8 | 15000 | 40 | 66 | +1.2~0 |

| I-HS-TCN-55C-R | 9.5~32 | 17 | 34 | 11000 | 55 | 78 | +1.4~0 |

| I-HS-TCN-65C-R | 12.7~38.1 | 46 | 92 | 9000 | 65 | 90 | +1.5~0 |

Iimpawu zesigcawu

Ukudibanisa umhlathi ogobileyo kubandakanya iihabhu ezimbini zetsimbi kunye ne-elastomeric "spider" element.Izigcawu ziyafumaneka kwi

ii-durometers zobunzima ezahlukeneyo, nganye ichongwe ngokulula ngombala wayo.

| Ukuqina | Umbala | Izinto eziphathekayo | Uluhlu lobushushu | Usetyenziso |

| 80 Unxweme A | Luhlaza | Polyurethane | -50 ~+80 .C | Ukudambisa okugqwesileyo |

| 92 Unxweme A | Lubhelu | Polyurethane | -40~+90 .C | Ukudambisa okuphakathi, izicelo jikelele |

| 98 Unxweme A | Bomvu | Polyurethane | -30 ~+90 .C | Ukusetyenziswa kwetorque ephezulu |

| 64 Unxweme D | Luhlaza | Polyurethane | -50 ~+120 .C | I-torque ephezulu, ubushushu obuphezulu |

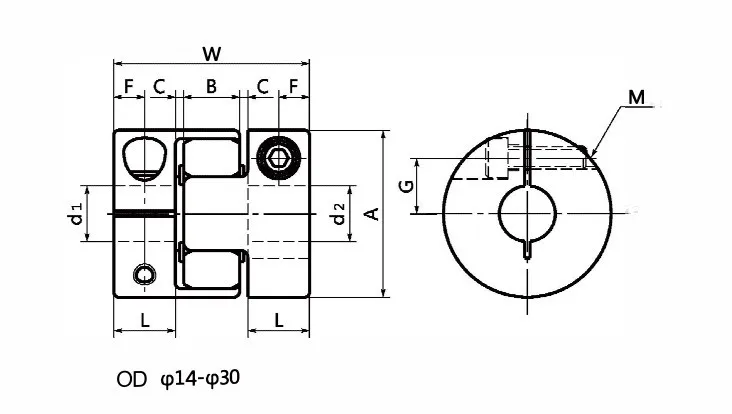

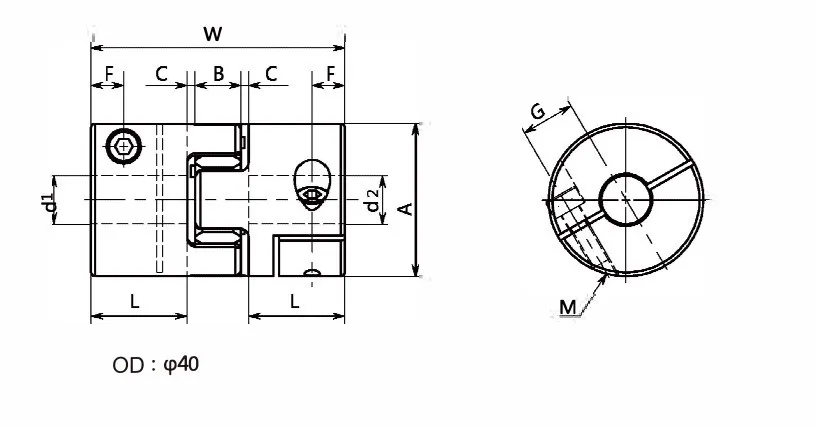

Ulwazi lomlinganiselo wokudibanisa

| A | L | W | B | C | F | G | M |

| 14 | 7 | 22 | 6 | 1 | 3.5 | 4/5 | M2/M1.6 |

| 20 | 10 | 30 | 8 | 1 | 5 | 6.5/7.5 | M2.5/M2 |

| 30 | 11 | 35 | 10 | 1.5 | 8.5 | 10/11 | M4/M3 |

| A | L | W | B | C | F | G | M |

| 40 | 25 | 66 | 12 | 2 | 8.5 | 14/15.75 | M5/M4 |

| A | L | W | B | C | F | G | M |

| 55 | 30 | 78 | 14 | 2 | 10.5 | 20/21 | M6/M5 |

| 60 | 35 | 90 | 15 | 2.5 | 13 | 24/25 | M8/M6 |